About us

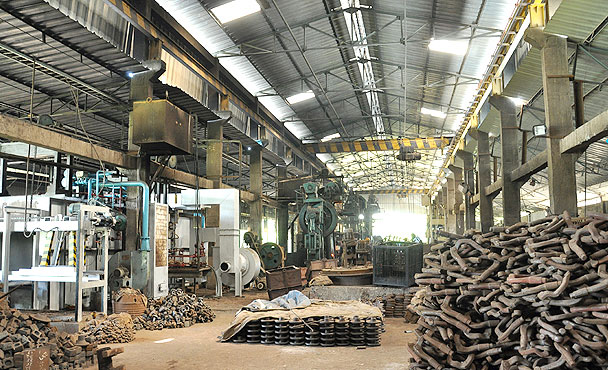

Ishmeet Forgings (P) Ltd., a small but fast emerging entity, is a steel drop forged company started in 2002, engaged in the manufacture and export of Carbon and Alloy Steel Drop Forged Components as per customer’s specifications. The manufacturing base of the company is located at Ludhiana, an industrial city of Punjab, which is 300 Km north of capital city, New Delhi. The company can boast of an annual sales of US$ 7.4 Million and employ 250 skilled & unskilled manpower. The company houses drop forge hammers with weight capacity ranging from 1.0T to 3.0T and have capacity to forge component weight up to 30 Kgs of single piece.The annual production capacity of the plant is to forge 7200 MT of steel.

Ishmeet Forgings (P) Ltd., a small but fast emerging entity, is a steel drop forged company started in 2002, engaged in the manufacture and export of Carbon and Alloy Steel Drop Forged Components as per customer’s specifications. The manufacturing base of the company is located at Ludhiana, an industrial city of Punjab, which is 300 Km north of capital city, New Delhi. The company can boast of an annual sales of US$ 7.4 Million and employ 250 skilled & unskilled manpower. The company houses drop forge hammers with weight capacity ranging from 1.0T to 3.0T and have capacity to forge component weight up to 30 Kgs of single piece.The annual production capacity of the plant is to forge 7200 MT of steel.

Vision

With a strong commitment on the export front Ishmeet Forgings Pvt. Ltd. is poised to become a leading OEM & Tier-I supplier of Steel Forgings and Machined Components to Diverse Sectors covering Automotive, Tractor & Farm Equipment, Commercial Vehicles, Container & Ship Building, Railways and Engineering Goods sectors worldwide.

Clients

The reliability of any organization lies in its quality customer base. During our years of long journey, we have earned the unwavering trust and high response of our clients through Quality Products coupled with Timely Delivery. Relying heavily on consistent quality records and sufficient infrastructure, IFPL has a highly quality conscious customers from Original Equipment (OE’s) in its kitty with whom the company has been doing business and growing at a steady pace.

Customer Satisfaction

To us at IFPL, serving customers with quality products with timely delivery is of paramount importance. Thus, our manufacturing and quality processes include the provision for best available raw material, state of the art technology inputs, documented quality procedures & processes and highly skilled and professional manpower at each level of organisational hierarchy.

Production Facilities

We Wish to introduce ourselves as a quality conscious manufacturer & exporter of steel forgings and auto parts.